Home > Products > Globe Valve > Sanitary Stainless Steel 304 Membrane Pneumatic Globe Valve with Positioner 1891

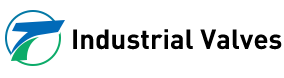

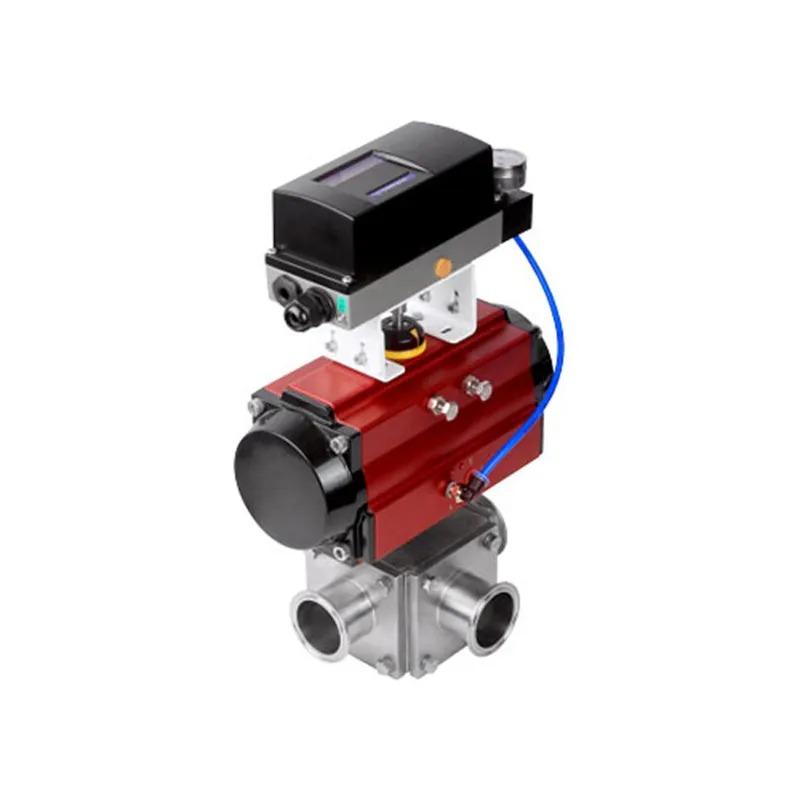

Sanitary Stainless Steel 304 Membrane Pneumatic Globe Valve with Positioner 1891

Sanitary Stainless Steel 304 Membrane Pneumatic Globe Valve with Positioner 1891Technical specifications:Size 1/2"-3", DN10-DN100 Material CF8/304, CF8M/316Connection Thread, Clamp, Flange, BSP, BSPT, NPT, DINWorking pressure 8 bar (standard) 10 bar (option)Working temperature 120 &or......

Send Inquiry

Product Description

Sanitary Stainless Steel 304 Membrane Pneumatic Globe Valve with Positioner 1891

Technical specifications:

Applications:

Golbe valve is a general switch in the automatic control system is widely used in printing, dyeing, bleaching, food, washing, chemical, water treatment, pharmacy and other automated machinery and equipment. It featured with water hammer protection, noise-free, reliable sealing performance.

Technical specifications:

Size | 1/2"-3", DN10-DN100 |

Material | CF8/304, CF8M/316 |

Connection | Thread, Clamp, Flange, BSP, BSPT, NPT, DIN |

Working pressure | 8 bar (standard) 10 bar (option) |

Working temperature | 120 ºC (standard) 180 ºC (option) |

Power supply | DC 24V |

Signal input | 0/4-20mA, 0/5-10V |

Signal feedback | 0/4-20mA, 0/5-10V |

| Operating mode | Manual: plastic handwheel, stainless steel handwheel, fine-tuning hand wheel |

Pneumatic: plastic and stainless steel actuators | |

Pneumatic control mode: valve positioner, process controller, control unit and position sensor | |

Application scope | printing, dyeing, bleaching, food, washing, chemical, water treatment, pharmacy and other automated machinery and equipment. |

Certificate | PTFE FDA177.5500 PED/97/23/EC |

Packaging details | standard exporting package or customerized |

Delivery details | Usually within 20 days after receiving T/T down payment |

Applications:

Golbe valve is a general switch in the automatic control system is widely used in printing, dyeing, bleaching, food, washing, chemical, water treatment, pharmacy and other automated machinery and equipment. It featured with water hammer protection, noise-free, reliable sealing performance.

Related Category

Ball Valve

Gate Valve

Check Valve

Solenoid Valve

Butterfly Valve

Other Valves & Parts

Control Valve

Globe Valve

Safety Valve

Angle Valve

Pressure Reducing Valve

Diaphragm Valve

Needle Valve

Exhaust Valve

Plug Valve

Steam Trap

Inlet Valve

Sampling Valve

Mini Pressure Valve

Blind Valve

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.